The time spent in the brooder environment (first 14 days of the broiler’s life) is a critical period in broiler production. And research has shown that there is a positive relation between early bird growth rate during the brooding stages and the final weights at slaughter. As such farmers would need to maintain and adhere to conditions needed within the brooder house in order to maximise on flock performance. Critical features of the brooder environment are; light, feed, water air quality, stocking density, biosecurity and heat. The highest mortality in a poultry house is experienced during the first 10 days of life and is due to:

· ‘’starve outs’’ – birds that do not eat or drink (fail to find feed and water).

· Gout-uric acid (nitrogenous waste products) build up in blood stream due to dehydration.

· Navel ill or ‘’omphalitis’’ – a bacterial infection of the umbilicus or yolk sac remnant of the chick.

This is why the management during this period is so essential to give your flock a good start. This article will articulate on the key brooder house management principles.

Light

Light is one important management tool in broiler production. Light will ensure that the chicks see feed and water points quickly. A single infra-red lamp is enough for 50 chicks. One parameter of light that needs attention is light distribution. Uneven light distribution may lead to poor bird uniformity. As such light needs to be distributed evenly within the brooder house. Additionally, poor lighting will hinder growth rate, thus the need to allow a good lighting intensity (around 30-40 lux is recommended from day old to day 7 of age and around 5 lux onwards).

Many broiler producers introduce what are called lighting programs. A lighting program is a documented system of controlling the time or period to which the birds are allowed light. Lighting programs differ from farmer to farmer and as well as from one stockfeed manufacturer to the other. Many broiler farmers use a lighting program that provides what is essentially continuous lighting. This system consists of a long continuous light period followed by a short dark period of between 30-60 minutes, such that the birds get accustomed to the dark should power cuts occur. Information from trials has suggested that:

• After 7 days of age around 5 hours of darkness may be optimum (4-6 hours).

• There is no reduction in growth rate to 39 days and possibly an increase to 49 days of age.

• Mortality due to sudden death syndrome (SDS or flips) and mortality and morbidity from ascites is reduced.

• The biological welfare of the birds is improved as normal behaviour is facilitated, an example is rest.

However, introducing a lighting program will greatly depend on flock performance. If farmer sees that the birds are under-performing, it will be wise not to introduce a lighting program, just to allow more feeding and improved growth performance.

Feed

Feed is another important tool in the brooder. It should be provided for, clean and dry. If the feed becomes moist, there is high risk of aflatoxin infection which leads to changes in performance that can be detected by low growth rate, poor feed conversion and low flock uniformity. Feed should be available always in the feeders to reduce losses due to unnecessary feed restriction or negligence.

Proper feeder to bird ratio should be maintained at 1:50 birds for chick trays and 1:100 for tube feeders. Opening up more space for correct bird/space ratio of not more than 12 target will reduce overcrowding the birds, which renders poor growth. From day old to 14 days of age, at least 6cm of feeder space per chick is needed. Whilst from day 15 to slaughter age they will need at least 10cm of feeder space per chick.

For the first 7 days, supplementary feeders (paper trays or lids) should be provided. The paper trays should cover around 80% of the house. Supplementary feeding will ensure that all the chicks are consuming feed and in addition improving growth performance and uniformity, given other brooding parameters are up to par. Similar with drinkers, feeders need to be adjusted to correct heights to reduce feed wastage from spillage.

Water management

Water is a vital ingredient of life. Water supplied to broilers should contain minimum amounts of minerals, as high levels would encourage increased excretion which would impose a need to increase ventilation management. Similarly to feed, clean and fresh water should be provided for at all times and vitamin/mineral stress pack is included for the first week. Inadequate water supply, either in volume or available drinker space will reduce growth rate. Water should be as cool as possible and drinkers must be easily accessible for the birds. Very cold or very warm water will cause reduced water intake.

From day old to day 7, farmers can use 4l water font at a rate of 1:50 chicks, which are replaced with 16l bell drinkers (1:100 birds) onwards or one nipple for 10-12 birds at 5 weeks. Drinkers or nipple lines should be placed at correct heights at which the birds are able to reach. These height adjustments are done as the birds grow and they should be made in such a way that the back of the bird levels with the base of the drinker from day 18 onwards. This helps in minimizing water spillage, which would cause increased litter moisture. It should be noted that, water requirement will increase in a hot day and vice versa on a cold day and also increases as the birds age. NB: Water requirement increases by approximately 6.5% per degree Celsius increase in temperature. Here is a basic water consumption guideline for broiler chickens from day old to 6 weeks of age;

Water consumption per 100 chicks per day

| Age (weeks) | Litres |

| 1 | 3 |

| 2 | 9 |

| 3 | 14.4 |

| 4 | 16.7 |

| 5 | 17.4 |

| 6 | 21.6 |

At six and 24 hour intervals following chick placement it is advisable to check the crop, to assess whether the birds have taken up enough water and feed. An empty crop would indicate that the birds have not found water and feed, a soft crop is indicative that the birds have enough water and feed, and a hard crop means the birds are feeding but not drinking enough water. Hence water consumption should be closely monitored as it is directly linked to feed intake.

Heat

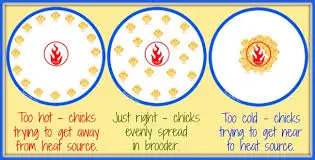

Chicks cannot regulate their own body temperature until they are around 12–14 days of age. Ideal body temperature must be attained by providing optimal environmental temperature. Preheating the house is vital as floor temperature at chick placement is important. Pre-heating the poultry house to about 33°C is advisable for chick placement. A single infra-red lamp is enough to heat up 50 chicks, whilst one drum heater will cater for 500 chicks. The normal body temperature of a broiler chicken is approximately 41°C. When the environmental temperature exceeds 35°C, the broiler is likely to experience heat stress. The longer the broiler is exposed to high temperatures, the greater the stress and its effects. Some effects of heat stress are experienced in the later stages of the broiler chicken, usually from 3 weeks going forward. For example ascites, one major cause of mortality at the later stage of the broiler induced by heat stress. Poor heat distribution can also have a negative result on bird uniformity. Priority ought to be taken to ensure even heat distribution within the brooder house. Bird behaviour is one indicator of heat distribution within the house.

The following table shows temperature requirements at different ages for broilers.

| Age | |

| Day old | 33 |

| Day 7 | 30 |

| Day 14 | 28 |

| Day 21 | 26 |

| Day 28 | 24 |

| Day 35 | 22 |

Air quality

Ventilation is key to controlling the brooder environment. It necessitates maintenance of acceptable air quality within the poultry house whilst keeping the birds within their comfort temperatures. While pre-heating prior to chick placement, it is advisable to allow minimum amounts of ventilation. The amount of ventilation will greatly depend on the heating being used. This will help in distributing heat evenly within the house, allow the bedding to remain dry and also eliminate harmful gases. Curtains are always opened from the top to bottom for ventilation, this will allow air to circulate properly within the house and limits the occurrence of draughts.

As the birds grow and start to produce more heat, higher ventilation rates are needed to remove heat and the products of respiration (moisture) from the house. You will realise that continued exposure to air contaminants results in respiratory diseases and poor bird performance, lest some degree of ventilation is allowed.

With diets containing high levels of protein and/or salt, there is noticeable increase in excretion of waste gases and water (urine). Hence ventilation management vs. heat management conflicts, result in poor brooding and mortality.

Stocking density

Stocking density refers to the space provided for, to a group of animals in this case broiler chickens. Stocking density has great influence on bird performance, uniformity and overall product quality. As such producers ought to maintain stocking densities within specified guidelines. The stocking density used from day 21 onwards is 10 birds per square metre, meaning 1000 birds would require 100 square metres of space in order to maximise on flock performance.

On the other hand, overstocking would increase environment pressure on the birds, leading to poor growth and conversely reduced profitability of the farm. Overstocking has also been linked to cause mortalities due to ascites, hence maintaining proper stocking densities would help minimise the occurrence of this syndrome. Additionally, overstocking tends to encourage rapid transmission of disease within a flock and outbreaks can be economically devastating.

Biosecurity

These are a set of measures put in place within animal production facilities to limit disease entry from the external environment. Diseases entry within a flock can occur in many ways which include, humans, new batches, contaminated equipment and vectors such as flies or wild animals. By putting in place biosecurity measures farmers can actually “limit” the possible introduction of disease within a flock. Here are some of biosecurity measures that can be put into place within broiler enterprises;

· Always start assessment from the younger birds, then older birds last.

· Controlling rodents and flies in the poultry house.

· Disinfecting footbaths and vehicles at points of entry to the poultry house.

· Providing a hand wash area.

· Keep other livestock at least 40m away from flock housing.

· Allowing a two week rest of poultry house before introducing another flock. Also disinfect poultry house during rests with a high pressure wash.

· Always provide clean safety clothing for workers and visitors.

· A perimeter fence should be present around the premises.

· Restricting entry into premises.

Good management practices within the brooder environment will ensure that broiler producers maximise on flock performance and inevitably capitalize on profits at finishing. Training and awareness are necessary tools that ensure the basic guidelines are put into practice.

Author : James Kabinda-a member of the Windmill Stockfeeds division (+263 774 225 873)/jameskabinda@gmail.com/kabinda@windmill.co.zw

For more details contact:

1) Mr Claude Ndavambi-Divisional Head of Livestock and Animal Health

ndavambi@windmill.co.zw

+263 772 433 496

+263 4 334911

2) Mr Tawanda Mthintwa Hove

Regional Depot controls and Online communication

hove@windmill.co.zw

tawandahove08@gmail.com

+263 773 878 939

+260 954 239 341