By James Kabinda (B.Sc Animal Production and Technology).

Often new beef producers want to know which feed they can use within their differing beef production programs. The major questions asked by new farmers in beef production is, what product amongst our beef range will be suitable within these beef production systems, what product is suitable according to season and also what product will be suitable based on other inputs (ingredients) they have? In most cases that we have encountered, farmers tend to have an opinion that these rations save similar purposes when it comes to how they influence the physiology of beef cattle. Well, both the usage and purpose of these rations differ significantly in terms of how they influence the physiology of cattle and also differ on how they are formulated to cater for cattle at different physiological and developmental stages and also in differing production systems. Chiefly the nutrient (energy and protein) requirements in beef production systems differ. Beef production systems can be grouped mainly into; meat (pen fattening) and breeding stock production. With pen fattening, the goal is increasing mass of steers or young animals and therefore increase turnover, maximising on profits within a short period of time. Whilst in the latter system, the goal will be to maintain live weights within breeding stock. This article will try to give an insight (or guidelines) on the usage and applicability of our beef rations, such that consumers of our product begin to appreciate how these products differ.

Pen fattening meal (straight feed)

A pen fattening system or feedlotting is when beef cattle are subjected to a diet balanced for protein and energy. When subjecting your animals to this system (pen feeding) they are first drenched against gut worms like roundworms, liver fluke and tapeworms. This will ensure maximum utilisation of the pen fattening meal feed by your animals and inevitably maximum growth performance. Windmill pen fattening meal is a tried and tested straight feed with a crude protein content of 13%, enriched with a rich molasses flavour. The molasses component of the feed stimulates appetite which enhances high feed intake. Additionally it is also balanced for Energy and Protein ensuring fast growth and high carcass weights and grades to maximise profits. This completely balanced meal is designed for finishing (fattening) beef cattle in pens over a 90 day period, meaning feeding for weight gain. Feeding rate will depend on factors such as, live weight and age of the animal, but normally averages between 10-12kg per head per day. A break in program is needed for the cattle to get accustomed to the feed and good quality roughage can be made available even when feeding in pens as the animals may need it.

Mabiko premix, Mabiko K and Mabiko/salt concentrate.

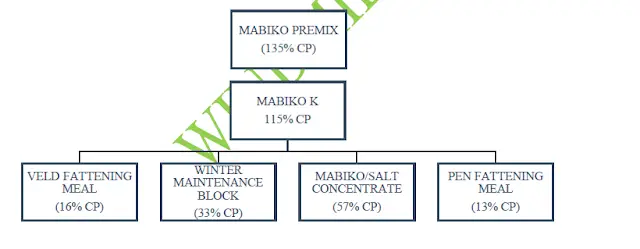

When one looks at these products, the first impression made is that they differ significantly. Well these products serve similar purposes, with the only difference being that Mabiko K is formulated from Mabiko premix and Mabiko/salt is formulated from Mabiko K. Mabiko premix is a beef concentrate containing a crude protein percentage of 135, whilst Mabiko K contains 115% CP. To make Mabiko K from Mabiko premix, one would mix 42kg of Mabiko premix with 8kg molasses. This dilution lowers the CP content of the premix to 115%, as such the resultant mix will be Mabiko K. One further step can be undertaken to produce Mabiko/salt concentrate (57%CP), whereby Mabiko K is mixed with Mabiko salt in the ratio 1:1. It should be noted that Mabiko/salt concentrate is the final product of Mabiko premix dilution or mixing and this ration can actually be fed as a block (or lick) to maintain the herd during the dry season.

Fattening rations using Mabiko K

Pen Fattening rations can also be formulated through use of Mabiko and maize and/or snap corn, where one can mix in the ratios 1:18 and 1:20 by weight respectively. These fattening rations made using Mabiko will give a normal Pen Fattening Meal and feeding rates are as per similar feed, though a break in program is recommended for Mabiko based pen fattening meals. This is to allow that the animal gets accustomed to urea. In addition to making pen fattening rations using Mabiko K, a veld fattening ration can also be formulated using Mabiko K. This ration is meant to finish cattle off the veld. In veld fattening Mabiko K is included at ratio 1:13 with whole maize. Intake is limited to 3kg/head/day to avoid toxicity and veld underutilization. And roughage can be made available (ad libitum) when feeding urea with maize. Our break in programme for the fattening rations can be carried out as follows;

ALLOWANCE

| DAY | Grain based diet (kg) | Snap corn (kg) |

| 0-4 | 2 | 7 |

| 5-8 | 4 | 8 |

| 9-12 | 6 | 9 |

| 13+ days | 8 | 10 |

Beef maintenance rations

Rations for maintaining beef during the dry season (Apr-Nov) cattle are formulated using our Mabiko K Beef Concentrate or Mabiko/salt concentrate. Mabiko K is a protein supplement that can only be utilised by ruminants, that is, cattle, sheep and goats. It contains major minerals (calcium, phosphorous, nitrogen, sulphur and manganese), vitamin A and Urea. Use of Mabiko K during the dry season will ensure maintenance of live weights, which is maintaining without loss or gain of the initial weight throughout the entire dry season. During the dry season, forage quality (that is nutritional composition and availability) deteriorates to levels below maintenance requirement. One such component of forage quality affected is Crude Protein content of the forage material which falls to levels below 7% CP (minimum required for maintenance), as a farmer it will be necessary to maintain the body condition of your animals under such harsh condition. Hence use of winter maintenance block (33% CP) using Mabiko K and maize or Mabiko/salt concentrate (57% CP) will improve utilisation of poor quality roughage such as veld grass, hay or crop residues. To make 100kg of the winter block, mix 25kg Mabiko K, 25kg Mabiko salt and 50kg maize meal. This is followed by addition of water, mixing then hardening for 4-7 days. Feeding rate of this block will depend on the physiological status and age of the animal, and it is as follows;

| ANIMAL CLASS | ALLOWANCE |

| Cows with calves | 750g/head/day |

| Cows due to calve | 500g/head/day |

| Long weaners | 400g/head/day |

| Weaners | 350g/head/day |

Improving roughage quality using Mabiko K.

Anaerobic breakdown of urea in the presence of adequate moisture produces ammonia. When the ammonia dissolves in water it produces a strong alkaline solution of ammonium hydroxide. This alkali solution reacts with the roughage material causing partial solubilisation of hemicellulose, lignin, silica and hydrolysis of uronic and acetic acid esters. A process termed roughage ammoniation. Ammoniation also leads to an increase in the hydration of the treated forage material as a consequence of disruption of the hydrogen bonds in cellulose. In other words it reduces the fibrosity of the feed that is softening it such that the animal spends less time and energy chewing it. Ammoniation is nutritionally and economically competitive to conventional feeds as it also improves the feed quality by enhancing its nitrogen content and hence the crude protein content, reducing the need to provide supplemental nitrogen through expensive protein concentrates. The optimum treatment of the forage is at 5% urea and the material is incubated for a minimum of 5 weeks. A 1000kg of roughage (wheat or barley straw) would need 150kg Mabiko K and 200 litres of water. Whist 1000kg of maize stover or veld grass would need 150kg Mabiko K and 300 litres water. It should be taken into consideration that where 200 litres of water is used, 6 litres of syrup is applied to 30kg roughage and where 300 litres of water is used, 10 litres of syrup is applied to 30kg roughage. To improve efficiency of the ammoniation, the material should be completely wet. Hence pre-wetting or increasing the water content by 50% of the material prior to treatment is advisable. Ammoniated roughage is used for maintenance and intake should be limited to 2.5kg/head/day, given in two phases, half the allowance in the morning and half in the evening.

Care and precautions taken when using Mabiko

Windmill Mabiko K is a multi-purpose protein supplement that can only be utilised by ruminants, that is, cattle, sheep and goats. It cannot be utilised by simple stomached animals e.g. pigs, horses and chickens. Though use is limited to ruminants, extra care ought to be practised when using Mabiko K. The following are guidelines for use of Mabiko K;

1. Introduce cattle to salt only for one week prior to feeding Mabiko (salt controls intake).

2. Introduce cattle to urea slowly for them to accustom to the diet.

3. If offering supplement separately as loose mix, adequate roughage must be provided separately.

4. Mix uniformly in rations, to avoid overconsumption of urea by individuals.

5. Do not feed Mabiko to cattle that have been starved or off feed for 2-3 days.

6. Do not feed excessive levels of urea, excess urea will lead to death in extreme cases.

7. Do not feed Mabiko to cattle that are in a poor condition or poor health.

8. Do not mix Mabiko with any soya bean containing ingredient as soya increases the rapidity of ammonia production.

9. Drinking water should be 200m away to avoid ammonia toxicity, for animals being fed Mabiko.

Addressing ammonia poisoning

The toxic effect of urea is due to a sudden production of ammonia and signs occur within 20 – 30 minutes of feeding. Feeding soya bean meal increases the rapidity of ammonia release. Severe abdominal pain follows ingestion of toxic quantities of urea. Nervous symptoms (excited appearance), weakness, difficult breathing, excessive salivation and bloat are consistent findings. At post mortem the carcass is pretty well negative because ammonia is so volatile, it dissipates rapidly and an elevated rumen pH is not often encountered.

Treatment of ammonia poisoning will greatly depend on the quantity of urea ingested and on how long after ingestion treatment is implemented. Vinegar is the remedy of choice as it neutralises the alkaline rumen content and reduces the amount of ammonia absorbed. Cattle will resist swallowing and consequent inhalation of the vinegar due to its burning quality prior to dosing. As a first line of defence, a whisky bottle of vinegar should be mixed with an equal quantity of water and molasses and then drenched to the animal. If the animal is going to respond, it will recover in 5 – 10 minutes. Further drenches of the same quantity can be given. The bloat that usually accompanies urea poisoning is a gas bloat, once the toxic effects of urea have been removed the bloat will disappear. Very often, the first sign of successful treatment is eructation (burping).

Chivako 8 (summer maintenance ration)

Besides maintaining your cattle herd during the dry season, farmers can actually maintain their cattle in a good productive state even in summer. Chivako 8 is one of our beef feed product range used for summer maintenance or supplementation of phosphorous. It is a ready to feed mineral supplement lick containing 8% phosphorous, enriched with molasses which gives the product its distinctive molasses smell and taste. This ready to feed lick is mainly used during the rainy season (Dec-May) to supplement phosphorous, and it encourages improved forage intake, growth rate and fertility. It is fed to young growing animals and to lactating cows. Daily intake of this feed is limited to 120g/head/day when fed as a loose mix, but lower consumption can occur when the feed is made into a block.

Beef survival meal

Windmill beef survival meal is a straight feed with a crude protein content of 11%, specifically formulated for those cattle in very dry areas or drought prone areas. Fundamentally it ensures the survivability of animals under such adverse conditions by helping in maintaining body condition of the herd. Allowance of this feed is approximately 10kg per head per day or fed as 3% of the body weight (whereby you calculate daily rations requirement per herd using herd average weight).

Product knowledge at farm level is key to understanding the requirements within differing beef production systems and it wouldn’t be wise to venture into beef productivity without at least the basic know-how of the product.